The targets service carries out the production and characterization of targets for different scopes. In particular, the activities are divided in:

- Targets for nuclear physics

- Targets for applications

- ISOL targets

Targets for nuclear physics

The main activities are the study and preparation of targets for nuclear physics experiments to be conducted at LNL or in foreign laboratories. In most cases, thin films of isotopically enriched metals are obtained using different techniques such as rolling or evaporation in vacuum. Different types of targets can be obtained:

- Self supporting

- With backing

- Strip-targets

- Sandwich-targets

- Plunger-targets

The instrumentation to carry out these activities includes many devices, including a fume hood designed to work with powders equipped with a high precision scale, a roller working under inert atmosphere, two high vacuum evaporators including a cryogenic one.

An example of a produced target can be found in: N.M. Uzunov et al., Phys. Med. Biol. 63 (2018) 185021, https://doi.org/10.1088/1361-6560/aadc88

High vacuum drier for the storage of targets

Targets for applications

The main activities are the development of innovative techniques to produce targets for cyclotrons, both for nuclear cross section measurements and medically relevant radionuclides production.

In general, a target is made of a precursor material deposited on a substrate of a proper material. Each target must satisfy specific requirements such as thermal and mechanical stability, thickness uniformity and low level of impurities. The production techniques should guarantee a minimal material loss (mostly isotopically enriched materials are used).

Targets for cross section measurements have thicknesses of about 1-20 µm so to, after being under irradiation, produce enough radionuclidic activity to be measured with HPGe detectors and to guarantee a small loss of energy of the impinging beam.

Targets for radioisotopes production are thicker, about 100 µm – 1 mm, depending on the desired nuclear reaction; in general, thickness is choses so as to maximise the radionuclide production yield minimising at the same time the quantity of produced contaminants. Moreover, since the yield is proportional to the beam current, the material and its structure are designed to sustain the highest possible beam power. To design these targets, advanced calculation methods such as computational fluid dynamics and finite element analysis are used to develop accurate models to foresee the target behaviour under irradiation. To validate these models, testing apparatuses have been developed, in order to evaluate the performance of thick targets in dissipating the power deposited by the beam.

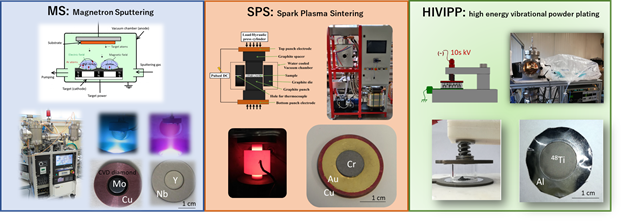

In the following figure the production techniques developed in the framework of the LARAMED project (link pagina LARAMED) are shown: Magnetron Sputtering (MS) (link servizio G. Keppel), Spark Plasma Sintering (SPS) and High Energy Vibrational Powder Plating (HIVIPP). The laboratory is also equipped with a machine for cryogenic grinding of powders.

Using MS and SPS, thick targets (100-400 µm) have been produced, to be used for irradiation in medical cyclotrons for the test production of medical radioisotopes (99mTc, 89Zr, 52Mn) (progetto METRICS). With HIVIPP, studied in the framework of the E-PLATE proect, thin (10 µm) isotopically enriched targets for cross section measurements have been produced (progetto REMIX).

More information can be found in in: H. Skliarova et al., Cyclotron Solid Targets Preparation for Medical Radionuclides Production in the Framework of LARAMED Project. J. Phys.: Conf. Ser. 1548 (2020) 012022, https://doi.org/10.1088/1742-6596/1548/1/012022

Bersagli ISOL

The main activities are the production and characterization of targets to be used in ISOL facilities such as SPES (link SPES). The produced materials are porous ceramics (carbides) to be used at high temperature (> 1600 °C) in high vacuum. In most cases, thin disks with a few mm in thickness are produced with different methods, such as carbothermal reduction, starting from solid precursors (powders) or with sol-gel based techniques.

The available instrumentation includes many devices such as a planetary ball mill to mix and grind powders, a high vacuum furnace to carry out thermal treatments, a helium pycnometer and a permeameter to characterize porosity.

An example of a produced target can be found in: S. Corradetti et al., Ceram Int. 46 (2020) 9596, https://doi.org/10.1016/j.ceramint.2019.12.225