The second accelerator, installed in Legnaro in 1971, is still as an electrostatic-type as the former CN, but the voltage terminal is 2 MV. Being the size smaller, the whole accelerator facility (i.e. accelerator with internal ion source, beam channels and all measurements points) is installed in a single experimental room.

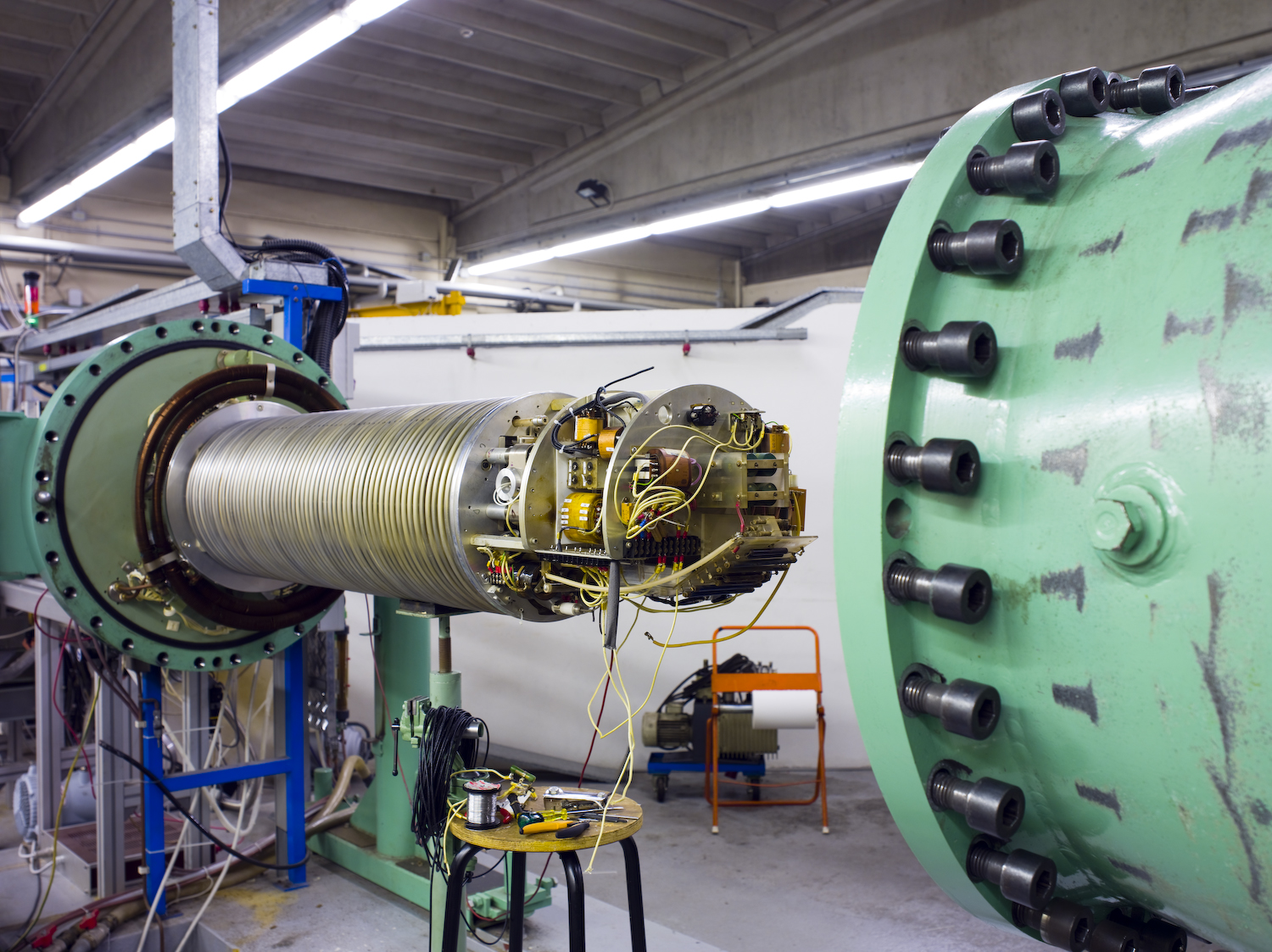

The smaller output energy available by such a compact-size accelerator makes it an ideal facility to promote nuclear reaction events with the first layers of target materials. AN2000, shown in Fig 4, is therefore primarily dedicated to the detailed investigation of materials surface properties, as well as to induce, on request, physical-chemical properties modifications on surface materials for a variety of purposes and applications.

By means of the AN2000 accelerator, detailed measurements for the elemental composition analysis of any material can be performed, by bombarding samples and identifying, through appropriate detection techniques, the particles or radiation which are produced in the beam interaction with material.

Protons or helium beams are used to probe the samples. Material analysis with this accelerator unveils the chemical composition and distribution profiles of the various constituent elements at various depths. Such nuclear, non-destructive, techniques are ideal for other fields of investigation such as archeology, for dating finds (solid samples). In environmental physics, the contamination level and pollution in air and water may be likewise determined with great precision.

The physics principle behind the ions beam generation and transport is identical to that of CN, as well as to any single-stage Van de Graaff electrostatic-type accelerators.

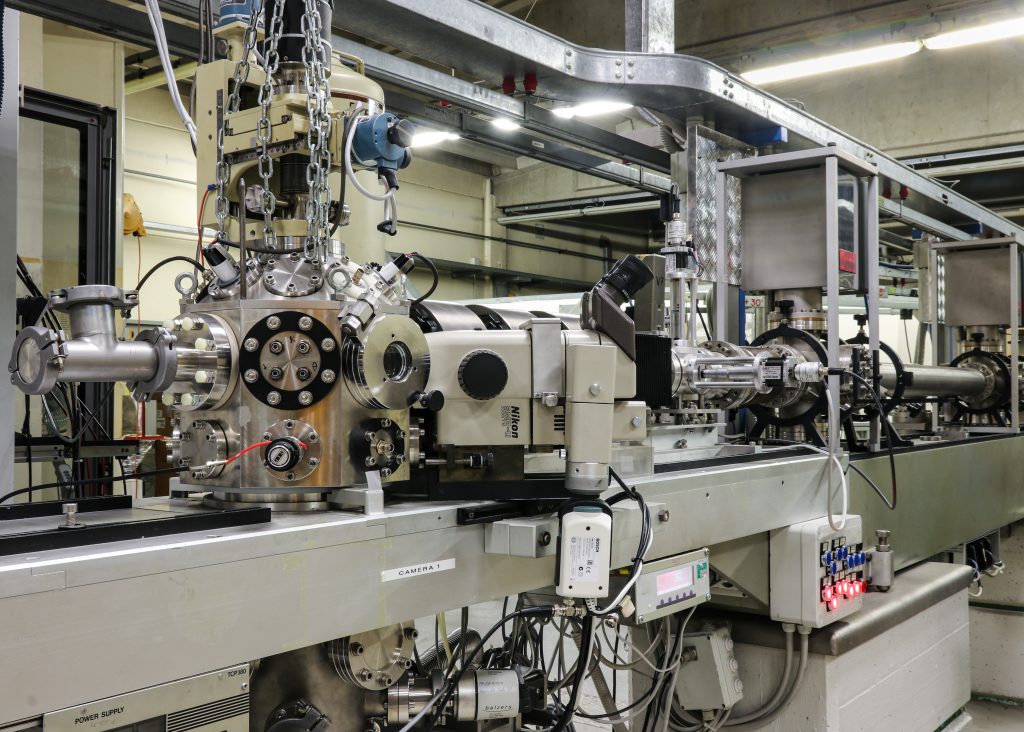

An apparatus which makes the AN2000 Legnaro facility unique is the so called “microbeam line” shown in Fig 5: a line able to provide an ions pencil beam, having just a few micrometer transverse size (1 micrometer is equal to one thousandth of a millimeter): it is an instrument able to probe or change the material surface behavior in a highly refined and precise way.